1. Vibration intrusion detector

1. Scope of application

Vibration detectors are basically surface controlled detectors. It can be used indoors or outdoors for perimeter alarms. The advantage is that early alarm can be achieved before the artificial protective barrier is broken.

The vibration detector can be applied indoors with open or dark compresses; Usually installed on walls, ceiling panels, floors or safes that may invade. When installed on the wall, the height of 2~2.4m from the ground is appropriate. The sensor is perpendicular to the wall. When it is applied outdoors, it is usually buried in the ground at a depth of about 10cm, and it is not suitable for burying in soft soil.

2. Installation points

(1) When the vibration detector is installed on the wall or ceiling panel, it must be firmly fixed with these objects, otherwise it will not be easy to feel the vibration. When used to detect ground vibration, the soil around the sensor should be compacted, otherwise the vibration wave is not easy to transmit to the sensor, and the detection sensitivity will decrease. The use of electric vibration detectors outdoors, especially on dirt, in the rainy season and winter, the sensitivity of the detector is significantly reduced, and the user should take other alarm measures.

(2) The installation position of the vibration detector should be far away from the vibration source. For outdoor applications, the vibration detector buried underground should be kept at an appropriate distance from other buried objects; Otherwise, the vibration of the surface layer caused by the shaking of these objects caused by wind blowing will also cause false alarms. Therefore, the distance between the vibration sensor and these objects should generally be maintained at a distance of more than 1~3m.

(3) Electric vibration detector is mainly used in outdoor buried perimeter alarm system. Its detection sensitivity is higher than that of piezoelectric crystal vibration detectors. The electrodynamic vibration detector magnet and the coil are prone to wear, usually checked once every six months, and the inspection interval when used in wet places is shortened.

Second, glass break intrusion detector

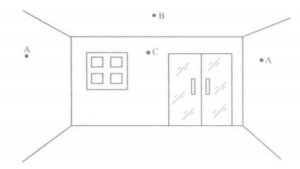

The installation position of the glass breaking detector is mounted on a hard wall or ceiling inlaid with glass, such as A.B.C. shown in Figure 7-15. The distance between the detector and the protected glass should not exceed the detection distance of the detector, and it should be noted that obstacles should not be placed between the detector and the protected glass to avoid affecting the propagation of sound waves; It should also not be installed in environments with excessive vibration.

1. Scope of application

Glass break detector is suitable for all places that need to guard glass shatterproof; In addition to protecting general doors and window glass, it can effectively control large areas of glass windows, display cabinets, kiosks, etc.

2. Installation points

(1) When installing, the acoustic and electrical sensor should be directly facing the main direction of vigilance. The sensor part can be properly concealed, but there should be no obstruction on the front of it. That is to say, the detector must have a clear line of sight on the protective glass surface, so as not to affect the propagation of sound waves and reduce the sensitivity of detection.

(2) When installing, it should be as close as possible to the glass to be protected, and as far away as possible from the noise interference source to reduce false alarms. In practice, the sensitivity of the detector should be adjusted to a suitable value, usually to detect the protected glass farthest from the detector, the sensitivity is too high or too low, it may produce false alarms or false negatives.

(3) Different kinds of glass break detector, according to their different working principles, some need to be installed next to the window frame (usually about 5cm away from the window frame), and some can be installed on the wall or ceiling near the glass, but the angle between the glass and the wall or ceiling should not be greater than 90, so as not to reduce its detection power.

(4) The installation method of infrasonic glass breaking high-frequency sound double-inspection glass breaking detector is relatively simple, and it can be installed anywhere in the room, only to meet the radius requirements of the detection range of the detector. Its installation location is shown in point A shown in Figure 7-15, and the maximum distance is 9m.

(5) A glass break detector can also be used to protect multi-sided glass windows. At this time, the glass breaking detector can be installed on the ceiling plate of the room, and the detection distance should be maintained at approximately the same distance as several protected glass windows to equalize the detection sensitivity.

(6) The detector should not be installed in front of the vent or ventilation fan, and should not be close to the doorbell to ensure the reliability of the work.

(7) Curtains, blinds or other coverings will partially absorb the energy emitted when the glass is broken, especially heavy curtains will seriously block the transmission of sound. In this case, the detector should be installed on the door and window frame behind the curtain or above the door and window; At the same time, in order to ensure the detection effect, on-site debugging should be carried out after installation.

(8) At present, some detectors also combine glass breaking detectors with magnetron switches or passive infrared detectors to make composite double detectors. This allows for further verification of glass breakage detection and intruder intrusion.

Third, infrared intrusion detector

(1) The installation orientation of the detector should strictly prohibit direct sunlight from shining into the receiver lens

(2) When the perimeter needs to be formed by more than two groups of receiving and transmitting mechanisms, different pulse-modulated infrared emission frequencies should be selected to prevent cross-interference.

(3) Correctly select the environmental adaptability of the detector, and the indoor detector is strictly prohibited from being outdoors.

(4) Outdoor applications should pay attention to concealed installation.

(5) Active infrared detectors should not be used in harsh climates, especially in areas where there is often dense fog and drizzle, as well as places where the environment is dirty or animals are often infested.

(6) The farthest warning distance of the outdoor detector should be calculated as 1/6 of its maximum beam distance.

(7) There can be no obstruction in the infrared optical path.

4. Passive infrared detector

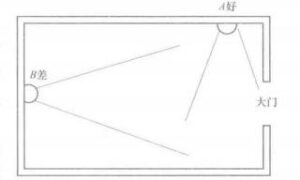

(1) The detector is most sensitive to the human movement of the horizontal cutting (that is, perpendicular to) the direction of the detection area, so this feature should be used as much as possible to achieve the best effect when arranging. As shown in Figure 7-16, the effect of point A arrangement is good; Point B is directly opposite the gate, and its effect is poor.

(2) When arranging, attention should be paid to the detection range and horizontal viewing angle of the detector. As shown in Figure 7-17, it can be installed on the ceiling (also in a transverse cutting method), or on a wall or in a corner, but pay attention to the relative angle of the detector window (Fresnel lens) to the warning surface to prevent dead angles.

Figure 7-17 Arrangement of passive infrared detector <>

a) Installed at the end corner to monitor the window; (b) Installation in face-filled surveillance doors and windows: (c) Installation in roof monitoring doors

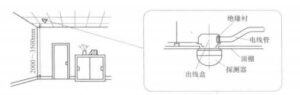

The all-round (360″ field of view) ceiling passive infrared detector installed on the indoor ceiling and its piping installation method are shown in Figure 7-18

Figure 7-18 Installation of passive infrared detector

(3) When choosing to install the wall or wall corner, the installation height is between 2-4m, usually 2-2.5m.

(4) The detector should not be aimed at strong light sources and doors and windows exposed to direct sunlight.

(5) The detector should not be aimed at the heater, air conditioning outlet pipe, it is best not to have air conditioning or heat source in the warning area, if the heat source cannot be avoided, it should be kept at least 1.5m away from the heat source.

(6) Be careful not to have tall shelters and interference from electric fan blades in the warning area, and do not install them in strong electricity.

5. Microwave and passive infrared composite intrusion detector

(1) Ceiling microwave-passive infrared detector, usually installed on the roof near the top of the key prevention part, should be installed horizontally.

(2) Corridor microwave a passive infrared detector, the field of view faces the direction of the corridor (passage), the installation position is subject to the effective blocking of the corridor (or passage), and the height is about 2.2m from the ground.

(3) When installing, the detector should usually point indoors and avoid direct sunlight towards the outdoor window. If evasion is not possible, the pointing and field of view of the detector should be carefully adjusted.

(4) Wall-mounted microwave-passive infrared detector, the installation height is about 2.2m from the ground, and the field of view and the possible invasion direction should be at an angle of 45″ (if limited by conditions, the sensitivity of the passive infrared unit should be considered first). The inclination angle of the detector and the wall depends on the protective area coverage requirements are determined.

When arranging and installing dual-technology detectors, it is required that the sensitivity of the two detectors be as balanced as possible within the warning range.

Microwave detectors are usually the most sensitive to objects moving along the axis, while passive infrared detectors are the most sensitive to the human body cutting the detection area laterally, so in order to make these two detection sensors in a more sensitive state, when installing a microwave and passive infrared dual technology detector, the detector axis and the direction of the protected object should be angled at 450 angles. Of course, the optimal angle is also related to the field of view pattern structure, so the actual installation should refer to the product manual.

(5) Environmental factors that can cause false alarms between the two detection technologies should be avoided.

(6) There should be no obstacles in the prevention area.

6. Microwave motion detector

(1) The penetration of microwaves to non-metallic substances has both good and bad sides. On the plus side, several rooms can be monitored with a microwave detector, and it can also be camouflaged with additional modifiers for easy knocking installation. The bad side is that if the installation is not adjusted properly, people walking outside the wall or vehicles traveling on the road and trees shaking outside the window may cause false alarms, the solution is mainly: the microwave detector should be strictly prohibited to install the outer wall and window of the protected room, and at the same time, the control range and its directivity of the microwave detector should be adjusted during installation. Usually the alarm detector is suspended at a height (1.5-2m from the ground), the probe is slightly downward, so that it points to the ground, and the detection coverage area of the detector is limited to the area to be protected. This minimizes the adverse effects of penetration performance.

(2) There should be no oversized and thick objects, especially metal objects, in the monitoring area, otherwise there will be a blind zone for detection behind these objects.

(3) Microwave detectors should not be quasi-fluorescent lamps, mercury lamps and other gas discharge light sources. The 100Hz modulated signal directly generated by the fluorescent lamp can cause false alarms, especially if the faulty flickering fluorescent lamp is more likely to cause interference. This is because the ionized gas in the flashing lamp is more likely to become a moving reflector of microwaves and cause false alarms.

(4) The microwave mobile detector has a certain range of detection of active targets in the warning area. Its warning range is a three-dimensional prevention space, and its control range is relatively large, which can cover the horizontal radiation angle of 60º-95º, and the control area can reach tens to hundreds of square meters.

(5) When more than two microwave detectors need to be installed in the same room, the microwave emission frequency between them should be different (usually about 25MHz difference), and should not be placed opposite each other to prevent cross-interference and false alarms.

(6) The probe of the microwave detector should not be aimed at the objects and parts that may move. Otherwise, these objects can become moving targets and cause false alarms

(7) The microwave detector should not be directed at large metal objects or objects with metal plating, otherwise these objects may reflect microwave radiation energy to the sidewalk or road of the exterior wall or exterior window. When pedestrians and vehicles pass by, the microwave signals reflected back by them may be reflected to the probe again through these metal objects, causing false alarms.

(8) Radar microwave detectors are indoor application detectors. When applied in outdoor environments, the reliability of its detection cannot be guaranteed.

Key points for the installation of various detectors

1 thought on “Key points for the installation of various detectors”