I. The role of glass break detectors in burglar alarm systems

In modern security systems, glass break detectors play a crucial role as an essential component of burglar alarm systems. With their unique working principle and high efficiency, they provide robust security for various locations. Glass break detectors primarily utilize advanced sensing technology to accurately identify the specific sound and vibration frequencies generated when glass breaks. When the detector senses these abnormal signals, it quickly activates the alarm mechanism, sending alerts to users or control centers through various means such as audible and visual alarms and remote communication. This real-time monitoring and immediate response capability allows glass break detectors to detect and address potential illegal intrusions at the first opportunity, effectively curbing criminal activity.

In burglar alarm systems, glass break detectors not only enhance the overall security level but also provide users with more comprehensive and meticulous security protection. Especially for locations with large areas of glass, such as shops, homes, and vehicles, glass break detectors undoubtedly add a solid layer of defense. Once the glass is damaged, the detector will immediately trigger an alarm, ensuring that users or the control center can quickly grasp the situation and take appropriate measures.

Glass break detectors play a crucial role in burglar alarm systems. With their accurate detection capabilities, efficient response speed, and intelligent linkage functions, they provide robust security for various locations. As technology continues to advance and application scenarios expand, glass break detectors will play an even more important role in the security field.

II. The Principle of Glass Break Detectors

The principle of the Focos glass breakage intrusion detector is mainly based on the dual technology of piezoelectric effect sound control and vibration detection.

First, the detector contains a piezoelectric ceramic sheet. This material twists and deforms under external force, generating an electric charge on its surface—this is the piezoelectric effect. When glass is struck or broken, it produces sound and vibrations at specific frequencies. The detector uses the piezoelectric effect to convert these sounds and vibrations into electrical signals for processing.

Specifically, the sound frequency emitted when glass breaks is approximately in the range of 10kHz to 15kHz , which is considered a high-frequency sound. The sensors inside the detector can monitor sound signals in this frequency band and effectively shield against interference from other low-frequency sound signals. Additionally, some detectors incorporate vibration detection technology, further enhancing detection accuracy by sensing the vibrations generated when the glass is struck.

The installation location and environmental conditions of a glass breakage detector can also affect its performance. Therefore, during installation, the detector should be placed as close as possible to the glass to be protected and away from noise sources to ensure accurate and reliable operation, enabling real-time monitoring and alarm functions for glass breakage events.

III. Product Features of the MD-343 Glass Break Detector

1. Directional high-precision microphone acquisition technology

Acquisition technology refers to the precise acquisition and identification of sound from a specific direction by using high-precision microphones, combined with specific acoustic design and signal processing algorithms. This technology can significantly improve the sound acquisition accuracy and anti-interference capability of glass breakage detectors, thereby enhancing the accuracy and reliability of the detectors.

2. Microprocessor-based sound analysis technology ( SAT )

Sound analysis is a technology that uses microprocessors to analyze and process sound signals. In glass breakage detectors, this technology is mainly used to perform detailed analysis and identification of the acquired sound signals in order to accurately determine whether a glass breakage event has occurred.

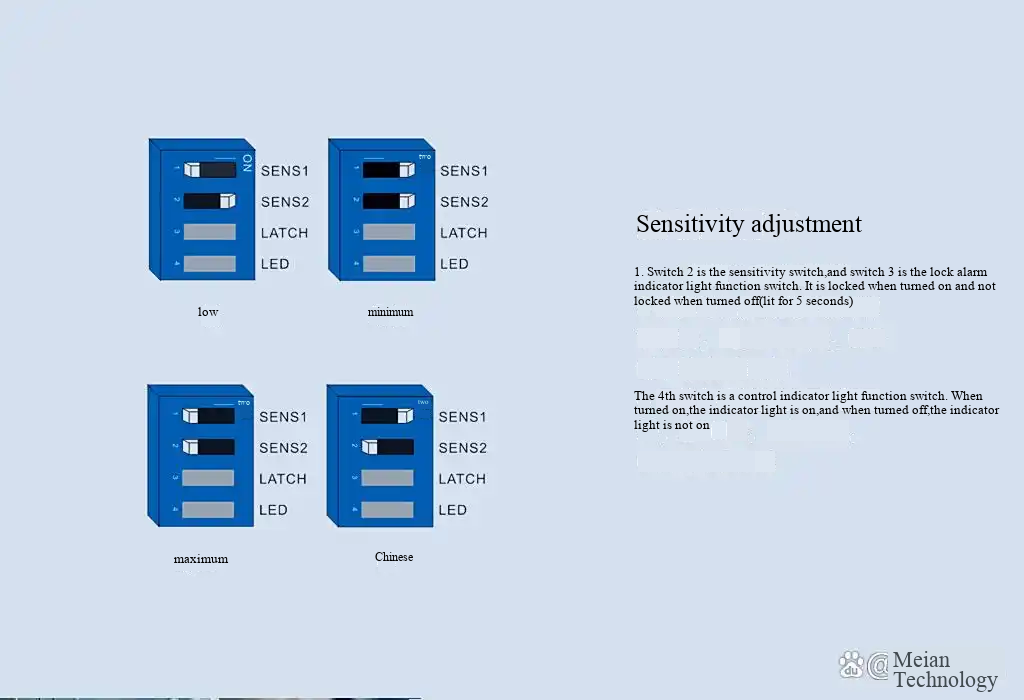

3. Adjustable sensitivity

Users can adjust the detector sensitivity according to the on-site application environment.

1. The switch is a sensitivity switch .

This switch is a function switch for locking the alarm indicator light. It locks when set to 0N and unlocks when set to 0FF.

( Lights up for 5 seconds )

Switch 4 is a function switch for controlling the indicator light. When set , the indicator light is on; when not set, the indicator light is off.

It features a combined front cover tamper-proof switch and a wall tamper-proof switch; triggering either switch will activate the tamper alarm. Refer to the wiring diagram to enable the tamper-proof function .

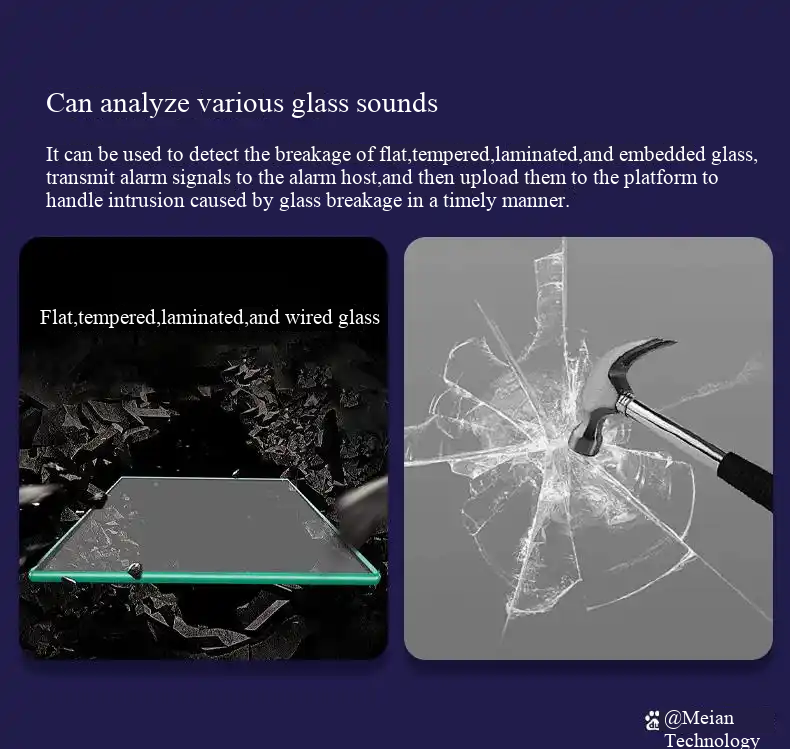

IV. Types of glass detected by the glass detector:

The MD343 glass breakage detector is a security device specifically designed to detect glass breakage incidents; it can detect a wide variety of glass types.

1. Detection of common glass types

Glass break detectors can typically detect the following common types of glass:

Ordinary glassFlat glass, the most common type of glass, is widely used in building doors and windows and other fields.

tempered glassSpecially treated glass has high strength and heat resistance, and is often used in automobile windows and high-end building doors and windows.

laminated glassComposed of multiple layers of glass and intermediate materials, it has excellent sound and heat insulation properties and is often used in high-rise buildings and luxury car windows.

Wired glassEmbedding metal wires or fibers into glass to enhance its impact resistance is commonly used in places requiring high security, such as bank counters.

Film-coated glassSpecial films are applied to the surface of glass to enhance its performance, such as explosion-proof and sun-proof properties. This technology is widely used in the automotive and construction industries.

Double-insulated glassIt consists of two layers of glass with an air layer or an inert gas layer sandwiched between them, and has excellent thermal insulation properties.

2. Detection of special glass types

In addition to the common types of glass mentioned above, some advanced glass breakage detectors can also detect certain special types of glass breakage events, such as:

Anti-tamper glassSpecially designed glass is difficult to remove or damage and is often used in places requiring high security.

Special material glassSuch as tempered glass and laminated glass, these glasses have special physical and chemical properties, and the detector needs to have a certain recognition ability to accurately detect their breakage events.

3. Rated detection glass thickness table

The minimum size for all types of glass is 28 square centimeters. The glass must be framed within a room or installed within a partition wall wider than 0.9m (36 in.). It can only be detected if both sides of the glass are broken. The safety film thickness for laminated glass cannot exceed 0.35mm (14 mils) .

V. Application and Installation

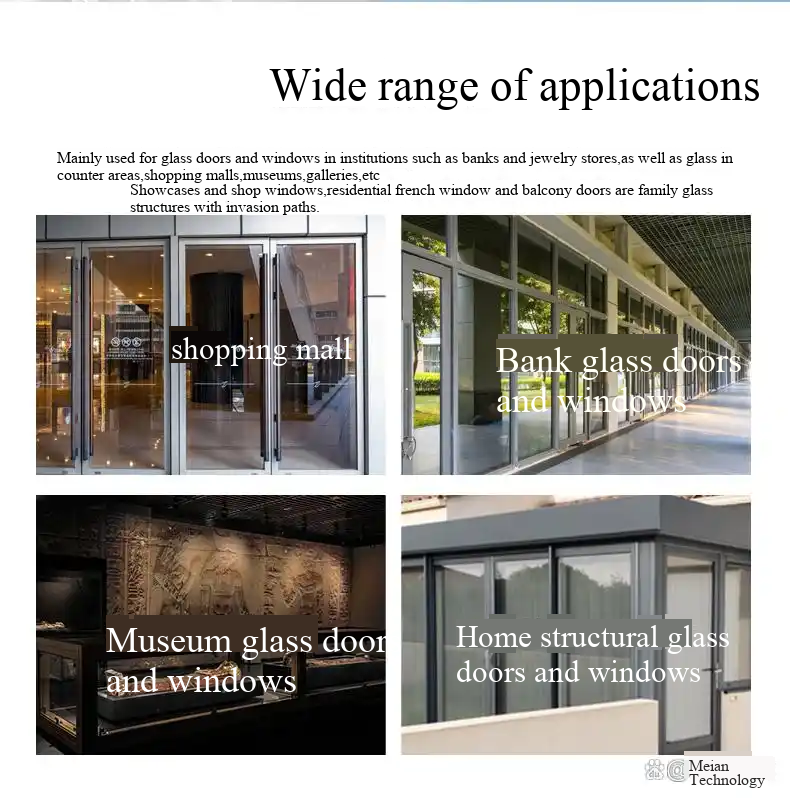

Application scenarios:

It is mainly used in glass doors and windows of institutions such as banks and jewelry stores, glass display cases and windows in counter areas, shopping malls, museums and galleries, and glass structures in homes where floor-to-ceiling windows and balcony doors are intrusion paths.